SCANNING ELECTRON MICROSCOPY (SEM) & ENERGY-DISPERSIVE X-RAY FLUORESCENCE SPECTROSCOPY (EDS)

BENEFITS OF HAVING AN SEM-EDS SYSTEM

To examine a particular feature or a microstructure of interest as reveled during optical microscopy, as well as to analyze composition of the feature of interest on a micro-scale, scanning electron microscopy and associated energy-dispersive X-ray spectroscopic microanalysis (SEM-EDS) is employed.

Sample examined during optical microscopy (from as-received to polished solid section or thin section or small sample extracted or a powder mount) is then subsequently coated with a thin conductive gold or carbon film for detailed SEM-EDS studies

Procedures for SEM examinations are described in ASTM C 1723.

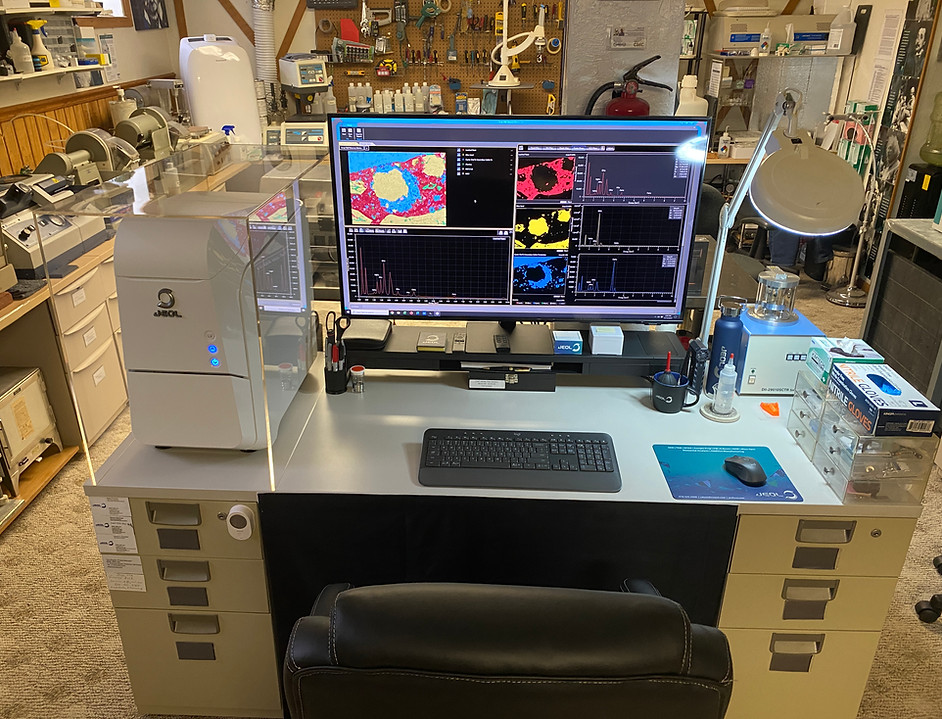

CMC employs a floor model Cambridge CamScan Series II and a bench-top JEOL JCM-7000 Neoscope scanning electron microscope both equipped with backscatter detector, secondary electron detector, and X-ray fluorescence spectrometer, and X-ray microanalysis software.

JEOL NEOSCOPE JCM 7000 & JEOL JSM-IT200

TWO NEW ADDITIONS TO SEM LAB

BACKSCATTER ELECTRON IMAGING

Based on average atomic number, different cement and concrete phases appear in different degrees of brightness/darkness in a backscatter electron image. The above plot of backscatter electron coefficient versus average atomic number shows phases like ferrite and free lime appear brighter in a backscatter electron image, whereas quartz the most common aggregate appear darker (voids appear the darkest). Backscatter electron images are the most common method of representation of microstructures of concrete and masonry.

ELEMENTAL MAPPING

X-ray elemental mapping (also called dot mapping) is a powerful technique to show compositional variations within and between different phases across a section of a concrete or masonry. The above four images show secondary electron image (top left, SED), backscatter electron image (top right, BSE), X-ray elemental map of distribution of silica (Si K-alpha, bottom left), and calcium (Ca K-alpha, bottom right) to show silica-rich sand aggregate distributed in a lime-rich matrix.

FAILURE INVESTIGATION OF CONCRETE

SEM-EDS analysis is particularly useful during failure investigation of concrete structures

Alkali-silica aggregate reaction is a common mechanism that causes expansion and cracking in concrete. Reactive aggregates in the presence of high alkalis and moisture in concrete during service participate in potentially deleterious alkali-silica reaction and causes subsequent expansion and cracking. A common application of SEM-EDS studies is in characterization of gel reaction products form from such a reaction and deposited in cracks and voids such as the one shown here. Analysis of ASR gel along the crack from a reactive aggregate to the neighboring paste is done at various points along the gel and shown in the compositional analyses Table beneath the backscatter electron image of ASR gel.

FAILURE INVESTIGATION OF CONCRETE

Elemental mapping of ASR reaction products

An extension of SEM-EDS studies in ASR-affected concrete is elemental mapping of gel reaction products such as the one from the previous backscatter electron image of ASR gel in a crack showing enrichment of calcium, silica, and potassium in the gel indicating a potassic silica gel composition that has caused expansion and cracking in the concrete.

FAILURE INVESTIGATION OF CONCRETE

Internal Sulfate Attack in Concrete

Sulfates released from oxidation of iron sulfide (e.g., pyrite, pyrrhotite) inclusions in aggregate can cause internal sulfate attacks after reactions with the aluminate phases in the hydration products of Portland cement. A typical microstructure of such an attack is formation of ettringite along aggregate-paste interfaces. SEM-EDS study is extremely useful not only to identify such ettringite reaction products along the interfaces but also assess the damage from such internal sulfate attacks.

POTENTIALLY UNSOUND CONSTITUENTS IN CONCRETE AGGREGATES

Pyrrhotite-related cracking in concrete

Pyrrhotite is an iron sulfide mineral commonly occur as a minor constituent in many aggregates. Its presence can potentially cause severe distress in concrete from expansions due to oxidation of pyrrhotite in the presence of oxygen and moisture, followed by internal sulfate attacks in paste from sulfates released from pyrrhotite oxidation. Therefore, a positive identification and quantification of pyrrhotite are essential to assess the damage. SEM-EDS analysis is very effective in determining not only the presence of pyrrhotite from its characteristic iron and sulfur contents, but also other iron sulfide (e.g., pyrite) and iron oxide (ilmenite, spinel) minerals in aggregates, as shown here from elemental analysis and elemental maps showing characteristic enrichments in iron and sulfur from pyrrhotite inclusions in a gneissic aggregate.

ANALYSIS OF HISTORIC MORTARS

SEM-EDS analysis is particularly useful during examination of

a modern or historic masonry mortar.

Due to characteristic difference in compositions of various binders, e.g., non-hydraulic lime (CaO dominants over all other oxides), variably hydraulic lime (CaO with variable SiO2 contents depending on degree of hydraulicity), dolomitic lime (high CaO and MgO), natural cement (CaO, SiO2, and MgO contents are high, high MgO and FeO contents are characteristic), and Portland cement (CaO and SiO2 contents are higher than all other oxides), SEM-EDS analysis of paste fraction of a hardened masonry mortar can provide many valuable insights about the original binder(s) used during masonry construction. The small boxed area in the top left image is enlarged in the middle backscatter electron image to analyze various areas of residual natural cement particle in point and area modes. Elemental maps show characteristic enrichments of calcium, magnesium, and silica in the residual natural cement (marked within the white dashed line) compared to the lime-rich paste around it.

CHARACTERIZATION OF MASONRY BINDERS

SEM-EDS analysis is particularly useful in characterization of various masonry binders from ancient lime binders to natural cement-lime binders to modern cement-lime binders

Compositional variations of paste from a masonry mortar are plotted for variations in silica and calcium oxide compositions of paste against cementation index (CI) after Eckel (1922). Cementation index, CI is [(2.8* SiO2)+(1.1*Al2O3)+(0.7*Fe2O3)]/[(CaO)+(1.4*MgO)]), which measures relative hydraulicity of paste e.g., non-hydraulic lime pastes have very low CI (< 1) compared to Portland cement pastes (CI is >1). Paste shows a continuous linear variation in plots of silica versus CI or CaO versus CI – which is the main characteristic compositional feature of a paste made using cement-lime binders in a cement-lime mortar.

CHARACTERIZATION OF

MASONRY BINDERS

SEM-EDS analysis is particularly useful in characterization of various masonry binders from ancient lime binders to natural cement-lime binders to modern cement-lime binders

Compositional analyses of pastes from different areas in a historic masonry mortar by SEM-EDS provide unequivocal clues to the composition of the binders used in the mortar as well as nature of the raw feeds used in manufacturing of those binders. Non-hydraulic lime, hydraulic calcitic or dolomitic lime, natural cement-lime binders provide characteristic differences in chemical compositions that are readily identified in SEM-EDS analysis. The above backscatter electron images and associates X-ray elemental analyses of four different historic mortars showed characteristic differences in their pastes’ compositions.

IDENTIFYING RAW FEEDS AND MANUFACTURING PROCESS USED IN DEVELOPMENT OF HISTORIC BINDERS

SEM-EDS is very useful to determine the original binder and raw feed used in production of the binder from analyses of residual phases left after the calcination, carbonation, and hydration

Detailed compositional analysis of residual and relic phases in paste provides clues to the compositions of original binders as well as the raw feeds used in the production of the binders. Here is an example of a residual natural cement particle from a historic mortar showing various phases from Ca-rich (Mg-Si-Al-poor) to Ca-poor (Mg-Si-Al-rich) compositions showing hydration of Ca-rich phases as well as calcination of original calcitic and dolomitic phases in the original argillaceous dolomitic limestone raw feed used in the production of this calcined and hydrated residue of a Rosendale natural cement in the historic mortar.

MATERIALS CHARACTERIZATION

Epoxy Terrazzo Floor

Elemental mapping in SEM-EDS is an excellent tool to characterize various construction materials, as in this case of a terrazzo floor the carbon and titanium footprints in respective elemental maps, along with calcium and magnesium maps show use of coarser dolomitic marble and finer calcitic marble chips in an epoxy-based binder where epoxy was mixed with a titanium oxide based pigment to impart the white color tone in terrazzo.

CHARACTERIZATION OF SHRINKAGE-COMPENSATING GROUTS

SEM-EDS analysis is an invaluable tool during investigation of expansion and cracking in various shrinkage-compensating grouts such as many gypsum-based anchoring grouts

Secondary electron image and x-ray elemental analyses of various marked areas around paste in a hardened shrinkage-compensating grout show the presence of: (a) profuse ettringite deposits, having its characteristic fibrous habit and shrinkage microstructure, marked within dashed lines, and measured in Probe No. 1; (b) Paste areas having no sulfate, listed in orange rows in the compositional Table, measured in Probe Nos. 2, 4, and 5; and (c) calcium silicate-sulfate-hydrates, in black, in Probe No. 3 as the three main hydration products of such grouts.

CLUSTER PHASE MAPS IN

JEOL JCM 7000

Residual Hydraulic Phase in

Historic Mortar

Iron Sulfide Minerals in Aggregate

Cracking Through An Alkali-Silica Reactive Greywacke

SCANNING ELECTRON MICROSCOPY, X-RAY MICROANALYSIS OF CONCRETES

Published in the very popular book entitled "Handbook of Analytical Techniques in Concrete Science and Technology" edited by V.S. Ramachandran and James J. Beaudoin from Noyes Publications, 2001 the chapter on SEM-EDS provides a good overview of applications of SEM-EDS in characterization and failure investigations of concrete. Various sections on this article are:

1.Introduction

2.Scanning electron microscopy, X-ray microanalysis

3.Optical Microscopy-Electro Microscopy Transition

4.Scanning Electron Microscope

5.X-ray Microanalysis

6.Concrete Under the SEM

7.Basic Microstructure of Concrete

8.Admixtures in Concrete

9.Interpretation of Concrete Deterioration from SEM-EDXA

10.Types of Attack

11.Chemical Deterioration from External Agents

12.Chemical Deteriorations from Internal Agents

13.Concrete Exposed to Marine Environment

14.Summary

15.References